Custom printing practices have changed in the past few years due to technological advancements that enhance the creative process. DTF transfers have taken the industry by storm with all these innovations, revolutionizing how custom designs are created and applied to different substrates. DTF stands for direct-to-film transfers, and DTF prints have gained much popularity in the industry because they are easy to produce yet deliver quality prints.

DTF technology has opened new possibilities that cannot be achieved using traditional methods such as screen printing and sublimation transfers. It presents a new, simple, cost-effective approach to custom printing with high flexibility. DTF can be used on cotton, polyester, blends, or even dark-colored fabrics.

Now, let’s discuss the specifics of custom DTF transfers and how they change the market.

What Are DTF Transfers?

DTF transfers involve producing a design on a film. The printed image is dusted with adhesive powder and set to dry. This process creates a DTF sheet that can be transferred to a substrate using heat transfer methods. Sublimation transfers are perfect for white or light-colored polyester fabric, while DTF prints can be applied to cotton, poly-cotton, and dark materials.

DTF technology has one major advantage: it can produce high-quality and effective designs on different materials. This makes DTF suitable for shirt transfers, tote bags, and other types of clothing.

How Does DTF Transfer Work?

The process of creating DTF transfers ready to press is straightforward yet effective:

Printing: A specialized printer prints the design on PET film. The process begins with color layers and then completes with a white ink base. This is because the colors of the designs stand out even when printed on dark material.

Adhesive Application: A small amount of powdered adhesive is rolled onto the printed layout.

Curing: The adhesive-coated film is then heated to melt the powder and make the film fit for use.

Heat Pressing: The film is then thermally transferred onto the material using pressure to form the design on the material's surface.

This method reduces a number of drawbacks of the conventional approaches, providing more options and faster results.

Benefits of DTF Transfers

1. Compatibility with Diverse Fabrics

Where sublimation prints are only printable on polyester fabric, DTF prints are on cotton, blends, and synthetic materials. This is a huge advantage for companies that receive different customer orders.

2. Vibrant Colors and Detail

DTF technology gives very clear and sharp designs with very bright colors. From a basic logo design to a complicated graphic, the custom DTF transfers are assured to deliver exceptional results.

3. Durability

DTF prints are highly durable, resisting peeling or fading even after multiple washes, making them suitable for long-term projects.

4. Easy to Use

With DTF transfers ready to press, the application process is quite easy. Creating high-quality designs with a small business or as an individual without much equipment is easy.

5. Cost-Effectiveness

While screen printing is inefficient if we want to print small quantities of items, DTF is ideal for small and large orders. This is particularly advantageous for custom orders where every design could be different.

How DTF Transfers Compare to Sublimation Transfers

Sublimation transfers have been used in custom printing for a long period. However, DTF transfers are becoming a much more flexible solution. Let’s compare the two:

| Feature | Sublimation Transfers | DTF Transfers | ||

| Fabric Compatibility | Limited to polyester or polyester-coated items |

|

||

| Color Vitality | Bright on white/light fabrics | Bright and detailed in all colors | ||

| Durability | Fades with time | Long-lasting and washable | ||

| Ease of Use | Requires specific fabrics | Works on almost any fabric |

Although sublimation is still a good choice for some applications, direct-to-film transfers are more flexible and dependable.

Applications of DTF Transfers in the Custom Printing Industry

The flexibility of DTF transfers has opened doors for numerous applications:

Custom Apparel

Shirt transfers are used by custom apparel businesses and individuals to design t-shirts, hoodies, and other clothing products. DTF's other strength is that it can print on dark or light fabrics.

Promotional Products

Companies use custom DTF transfers to brand tote bags, caps, and other promotional materials.

Small Business Solutions

Entrepreneurs find DTF transfers ready to press, easy to set up at low costs, and produce quickly, allowing for better handling of custom orders and new trends.

Hobbyists and DIY Enthusiasts

Since DTF sheets are ready to transfer, crafters can easily create designs without requiring many tools.

Why is DTF Revolutionizing the Industry?

Several factors contribute to the rising popularity of DTF transfers in custom printing:

Efficiency

It is faster and requires fewer resources than other methods, such as screen printing.

Customization allows you to create detailed, multiple-color designs suitable for unique and one-off prints.

Accessibility

The great thing about using ready-to-transfer DTF sheets is that you don't necessarily have to be a large enterprise or company to get professional-looking prints.

Versatility

DTF prints can be easily applied to various materials, whether cotton, polyester, or even blends.

These benefits have made DTF transfers one of the market's most innovative means of custom printing.

The Future of Custom Printing with DTF Transfers

With technological advancements, custom DTF transfers are only expected to improve. Improvements in ink technology, curing methods, and printing machinery will also help improve direct-to-film transfers.

In particular, businesses would be quite profitable to invest in DTF transfers that are ready to press. The capacity to satisfy the needs of various customers while still producing quality work guarantees growth and success. For hobbyists, it opens up a world of creative possibilities.

Conclusion

DTF transfers are revolutionizing the custom printing processes. These are not like the conventional techniques; they are flexible, resistant, and simple to implement. Whether you want to print shirt transfers for your business or create a custom gift, DTF prints will impress you.

Custom printing has changed, and direct-to-film transfer is the new revolution. More and more people are realizing the advantages of custom DTF transfers, and this technology is expected to spread widely in the coming years as the go-to method for personalized designs.

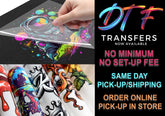

Get In Touch!

Digital Print Factory is one of the premier suppliers of custom DTF (direct-to-film) transfers that produce high-quality prints for any fabric. We guarantee quick turnaround time since orders are printed and dispatched within one day. We offer their services to small and big companies, as well as to those who are interested in customizing their clothes or accessories.