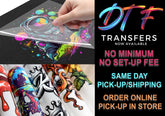

DTF Transfer vs. Screen Printing: Why DTF is Transforming the Printing Industry

The garment printing industry is evolving, and DTF transfer (Direct-to-film transfer) is a leading innovation. Screen printing has long been used to produce custom apparel. However, DTF heat transfer is more versatile. It's an easy-to-implement and innovative method that must be considered. This article will discuss DTF, how it functions, and why it is replacing screen printing as the preferred technique.

What is a DTF Transfer?

DTF, or direct-to-film transfer printing, is a method in which designs are printed on a special film and then heat-pressed on the fabric. Unlike screen printing, where ink is forced through meshes onto the fabric and stencils are used, DTF heat transfer uses sophisticated printers and adhesive powders to produce high-quality prints.

How Does DTF Work?

Here's a step-by-step procedure of the DTF printing process.

Design Creation

The process starts with creating designs on the artwork using graphic software. DTF supports bright colors, gradients, and fine details, making it suitable for customization.

Printing the Design

The design is printed on PET film using a DTF printer. The printer works with CYMK inks and white ink to produce bright, solid designs that do not fade or are not see-through on any fabric.

The print includes a reverse image of the design, which will be transferred face-down onto the garment.

Applying Adhesive Powder

After that, the printed film is coated with a special adhesive powder. This powder remains on the design area and makes the design stick to the fabric during the heat transfer process.

Curing the Design

This film is then exposed to a curing station or heated to activate the adhesive. This step ensures that the powder fuses well with the ink.

Transfer to Fabric

The prepared DTF transfer is then applied to the fabric and heat-pressed, transferring the given design to the garment through heat and pressure.

Peeling the Film

When the transfer cools down, the PET film is removed, leaving the design well stuck on the fabric. The result is a vibrant, durable, and flexible print.

Screen Printing- A Traditional Technique

It is a popular and traditional printing technique. It applies ink through a stencil and a mesh screen onto the fabric. Since each color in the design needs a separate screen, it is suitable for designs that cannot have many colors.

While screen printing has been a favorite for bulk orders, it has several challenges.

Complex Setup

Creating screens for multi-color designs takes a lot of work.

Limited Design Options

Frequent or complex patterns are hard to create.

Material Restrictions

Screen printing suits smooth, flat surfaces like cotton.

High Cost for Small Runs

Setup costs make short or custom orders less practical.

Comparison Table: DTF Transfer vs. Screen Printing

|

Feature |

DTF Transfer |

Screen Printing |

|

Setup Time |

Minimal – design is printed directly onto the film |

Lengthy – requires screen preparation |

|

Fabric Compatibility |

Works on all fabrics (cotton, polyester, blends, etc.) |

Limited to certain fabrics |

|

Design Complexity |

Handles detailed and multi-color designs easily |

Best for simple designs with fewer colors |

|

Durability |

Highly durable, resists cracking and peeling |

Durable but may fade or crack after some washes |

|

Cost for Small Orders |

Affordable – no setup costs for short runs |

Expensive – high setup costs for small batches |

|

Eco-Friendliness |

Uses minimal ink and adhesive |

Generates ink and water waste |

|

Print Quality |

Lively, high-resolution prints |

Decent but less suited for fine details |

Advantages of DTF Heat Transfer

Versatility

DTF transfers ready to press can be applied to cotton, polyester, leather, denim, and numerous other fabrics. This makes them ideal for many tasks, such as custom t-shirts, caps, bags, etc.

Cost-Effectiveness

Custom DTF transfers do not incur screen setup fees! This feature makes them suitable for small businesses and one-time design projects.

Ease of Use

The process is relatively simple. All needed are a printer, adhesive powder, and a heat press. Even beginners can achieve high-quality professional results.

No Color Restrictions

Screen printing has problems with gradients and fine details, whereas DTF prints can handle vibrant and multicolor designs.

Durable and Flexible Prints

Direct-to-film transfers are designed to adhere well to fabric and resist fading or peeling, even after repeated washing and use.

Fast Turnaround

The quick process of creating DTF transfers ready to press means you can fulfill orders faster, which is essential for growing businesses.

Why DTF is Taking Over the Screen Printing Industry

This is not just a trend but a reaction to a need in the market for products that are versatile, of high quality, and deliver a high level of performance in the print industry. Here's why DTF is rapidly gaining popularity:

Consumer demand for Customization

Customers are looking for individuality and customization, and with custom DTF transfer, it is now affordable to print small, detailed designs.

Lower Entry Barriers

Establishing a screen printing company is very costly, especially for the machinery and the space where the business will be operated. DTF printing requires fewer materials, making it ideal for small companies just starting.

Environmentally Friendly

As companies move towards sustainability, DTF prints are even more environmentally friendly because they produce minimal waste and use ink effectively.

E-commerce Growth

The on-demand printing businesses have mandated the use of DTF transfers to enable the production of orders for shipment.

Conclusion

DTF heat transfer is not just a screen printing technique! It’s an excellent method that addresses many of the industry's traditional challenges. Due to its flexibility in design handling and more affordable pricing for smaller orders, DTF is transforming the process of custom garment printing.

With customers and companies asking for more customized, productive, and eco-friendly solutions, direct-to-film transfers are at the forefront of the future of printing. If you are a small business owner, a fashion designer, or a print-on-demand entrepreneur, DTF transfers ready to press are the solution you need.

While screen printing still needs to be updated, DTF heat transfer is the new king in the printing industry.