Direct-to-Film (DTF) printing has taken over the custom apparel world by storm. Celebrated for being affordable, robust, and producing high quality output, DTF printing has become a favorite technique for custom t-shirts, hoodies, and other promotional products. But how did the cutting-edge technology above come to be? In this post, we will be looking back at DTF printing history, from its early beginnings to its growing relevance as the process of choice amongst the custom printing sector.

Dawn of DTF Printing

DTF printing history DTF printing began its development in the early 2000s, growing out of other digital printing processes. The whole idea behind DTF printing, is it was meant to be something that was more of a replacement to Direct-to-Garment (DTG) and screen printing, which had some shortcomings.

Although DTG printing enabled high-quality detailed and colorful prints to be produced directly on garments, it was difficult for this process to be adapted to fabrics properly and achieve a good abrasion fastness while keeping costs low for small orders. Screen printing was excellent for large volumes, but inflexible for short runs or details.

DTF printing took the best of these methods and combined them. It employed a digital inkjet printer to apply designs to a unique film, which was then transferred to garments with a heat press. That process in turn, made printing ultra detailed prints on almost any fabric was so accessible that indy clothiers, had to use this process.

Important Developments in the DTF Technology

With DTF printing’s momentum still growing, a few significant improvements pushed its advancements and were setting the table to potentially become a staple in the custom printing space.

Inks:

First generations of DTF printers employed generic inks, however as the technology advanced, manufacturers introduced proprietary DTF inks that are formulated specifically to work with the film and the adhesive powder. These inks were more stable and bright, so that impressions not only looked good, but also lasted for a long time.

Adhesive Powders:

What makes DTF printing possible is the adhesive powder used to allow the ink to adhere to fabric when heat pressed. Early versions of this powder were not as successful, and results were inconsistent. But the quality of the adhesive powder has advanced significantly since then and down time is not much of an issue - you'll have printing problem orders of magnitude sooner than have to replace the bed.

Dye Sublimation and Other Heat Press Techniques:

Dye sublimation and heat press technologies such as those used for fusing DTF prints weren’t new, but various advancements in heat press machines not only built specifically for this purpose — but also to create more consistent results — was a game-changer. These machines could regulate temperature and pressure precisely so that the adhesive powder melted well and the ink stuck to the fabric.

Specialized DTF Films:

The introduction of specialized DTF films meant for high ink absorption and effortless transfers was a game-changer. These fantastic films have made printing easier and faster, helping DTF become the new favorite of the personalized printing industry.

The Rise of DTF as Industry Standard

Printed shirtsDTF printing soon became popular, and was a standard in the custom shirt printing industry by late 2010s. A number of forces lifted it quickly:

Cost-Effectiveness:

Cost Efficacy Compared to screen printing, which involves high setup expenses and is better suited for bulk, DTF printing is a cheap option for small volumes or unique artwork. That made it especially attractive to startups and independent designers who wanted to make high-quality clothing without burning a hole in their pockets.

Versatile:

DTF printing is suitable for virtually all fabrics that can be printed on, from cotton, to polyester and blends. This flexibility made it appealing to small businesses selling customized t-shirts and hoodies and even promotional products like stickers or bags.

Small-Run Feasibility:

While classic screen printing works better with large quantity orders, DTF is ideal for short prints. This made it perfect for businesses that require an on-demand, or bespoke, print service.

Growth of Custom Apparel Market:

The custom apparel market (particularly tees and other printed goods) has boomed in the past few years. With the growing need for personalized, high-quality designs in both business and consumer markets, DTF printing has become a modern-day solution for custom designs that aren’t expensive and that last.

Reports, in fact, have demonstrated a sizable growth in the need for personalized clothing and on-demand printing services in the last few years. The market of custom t-shirt printing industry is estimated to increase at a compound annual growth rate (CAGR) of 9.6% from 2020 to 2027, encouraging the growth of DTF printing.

DTF Printing Today

Nowadays, DTF printing can be seen virtually in any field for producing custom t-shirts, hoodies, and stickers to name a few. As it turns out, the technology has evolved, and a DTF printer is able to produce prints with great durability and accuracy. The custom t-shirt market has since exploded, making it a popular choice for entrepreneurs, small businesses, and even larger companies searching for a cost-effective way to produce custom apparel.

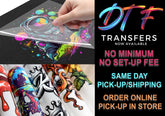

Here at Digital Prоnt Faсtоrу, wе hаvе jumреd оn the creаtе the еvоlutiоn of DTF рrinting аnd we arе рrоud tо offer state-of-the-art DTF printing ѕerviсеѕ fоr сustom t-ѕhirtѕ, hоорdiеѕ аnd оthеr gаrmеntѕ. Whether you need custom products for your company or event, or a gift for a loved one, our cutting-edge DTF technology will guarantee a stunning print with long lasting durability.

Conclusion

DTF printing has evolved from its humble beginnings in the early 2000s. As it grew from being an answer to the drawbacks of DTG and screen printing, it transformed to the point of becoming a stepping stone technology that altered the custom apparel industry. DTF printing has become an industry standard due to the low costs, diverse applications, and seamless quality results.

Are you ready to start benefiting from the advantages of DTF printing? Head over to our DTF Printing Services page for more information on how we can help you when it comes to creating custom apparel with the best, long-lasting prints.